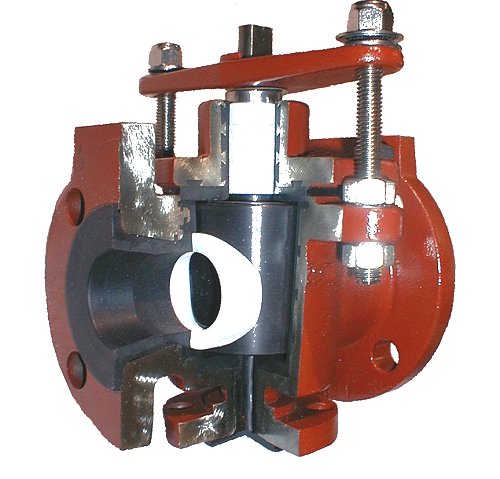

Model 790 Double Block and Bleed Valves

ChemValve has an innovative design for your double block and bleed needs. You will get all the advantages of the model 790EB Fully Lined Plug Valve but suitable for true double block and bleed requirements for isolation.

ChemValve has an innovative design for your double block and bleed needs. You will get all the advantages of the model 790EB Fully Lined Plug Valve but suitable for true double block and bleed requirements for isolation.

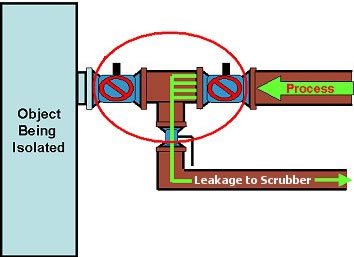

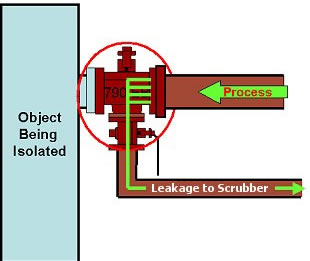

The ChemValve design reduces the need for two valves and a bleed valve to one valve and a bleed valve. Our double block and bleed valve has an upstream seat and a downstream seat. Then a bleed pipe runs down from the middle of the valve to insure isolation. This substantially reduces the cost by eliminating extra valves and spool pieces. Also, we eliminate potential emissions and leak paths associated with multiple flange connections. The diagram below depicts a typical double-block-and-bleed set up and one with the ChemValve Model 790EB-150-DBB:

Typical DBB Instillation |

ChemValve Model

790EB-150-DBB |

|

|

|

• 3-PFA Lined Ball Valves (2-3”,1-1”) |

• 2-PFA Lined 790-EB (1-3” DBB,1-1” Std.) |

The ChemValve Model 790EB-150-DBB has a bottom flange that is a true 1” ANSI class 150 pound rated flange. This valve can be used in conjunction with a sight glass to ensure sealing integrity in any critical seating application. The use of the model 790EB-DBB reduces the risk of manual errors and the higher risk of valve problems due to multiple installations. The model 790EB-DBB is a much more compact installation, this makes it much more suitable for tighter spaces.